Stokes unfinned tubular elements are high-performance heating components designed for industrial heating applications. Also known as tubular elements, these heaters are constructed from a corrosion-resistant alloy and are engineered for durability in demanding environments.

These elements are commonly used in:

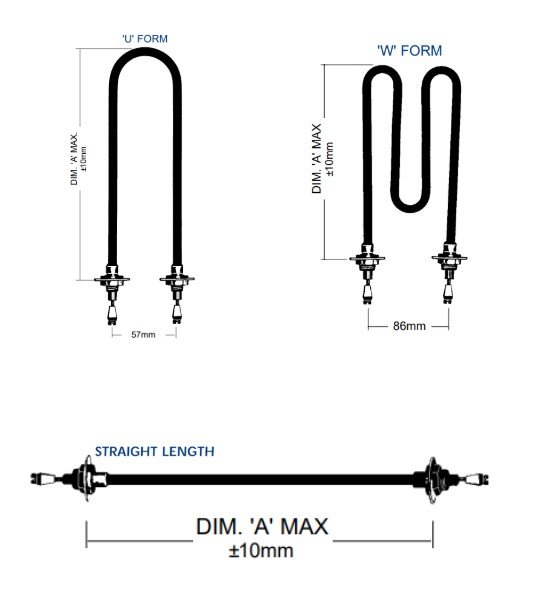

Stokes offers a variety of standard and custom-built tubular elements to meet specific heating requirements. When an application demands a unique length, wattage or other specification, Stokes can design a tailored solution to ensure optimal performance and efficiency.

The StokesAP Industrial team is based at our Victorian Head Office.

2/170 Rooks Rd

Nunawading VIC 3131

Australia

Phone: 1800 333 191

Email:

Opening Hours: 8:00AM to 4:00PM - Monday to Friday